Case Study – Precision CNC Machining for Medical Tools

.png)

Buyer Location: United States

Industry: Medical Devices

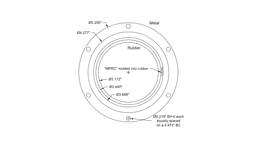

Project Type: Precision CNC machining & assembly of “Allen Tool” and “HV Retractor Handle”

Requirement:

-

Fully assembled Allen Tool & HV Retractor Handle

-

Timed thread on HV handle tip to fit existing blade inventory (sample provided for fit verification)

-

Connecting rod in titanium

-

Extremely tight tolerances & small dimensions for CNC machining

-

Quote for 100 pcs, delivered in batches of 25 pcs (every 6–9 months)

-

Separate pricing for setup fees & 1st approval sample

-

Suggestions for shipping, HS code optimization, and cost-effective logistics

Challenge:

-

Tight tolerances and very small CNC parts meant many vendors refused to bid

-

Buyer needed competitive pricing while maintaining high-quality machining standards

-

Requirement for ongoing repeat orders with precise batch delivery timelines

Our Solution:

-

Leveraged our network to identify specialized CNC vendors capable of meeting precision & tolerance requirements

-

Sourced 3–4 competitive quotes from Indian vendors

-

One vendor’s quote matched the buyer’s target price while meeting all technical specifications

-

Shared tariff & logistics suggestions to help buyer optimize overall landed cost

✅ Outcome:

-

Buyer is in the process of closing the deal with our recommended Indian vendor

-

Vendor committed to delivering approval sample within the required timeline and batch delivery schedule

-

Project continuity ensured through reliable supply chain support

Buyer’s Feedback:

“Finding MFG helped us find capable vendors for a complex, high-precision project when most suppliers weren’t willing to take it on.”